High-Performance Non-Destructive Testing (NDT) for Demanding Industrial Applications

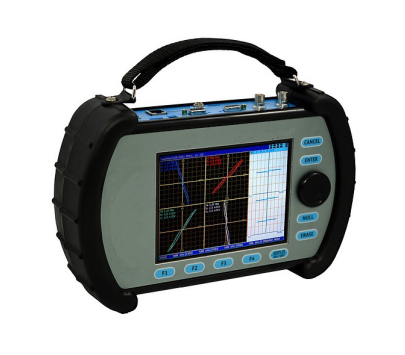

The FET99ST is a state-of-the-art, portable, and intelligent digital eddy current flaw detector, engineered for precision and versatility. Its robust and lightweight design makes it the ideal solution for online, offline, and in-the-field flaw detection of a wide range of metal components. From automotive parts to metal pipes, rods, and wire, the FET99ST delivers reliable and accurate results, ensuring the quality and integrity of your products.

Key Features & Advantages:

Advanced Flaw Detection: Excels at identifying both longitudinal cracks and transverse defects in metal bars, rods, and wire rods. It offers high sensitivity for detecting surface-breaking and near-surface cracks, as well as submerged joints.

Dual-Channel Technology: Equipped with independent testing channels, the FET99ST can drive combined probes (absolute and differential coils) for simultaneous data acquisition. This allows for comprehensive and efficient inspection in a single pass.

Intuitive Data Visualization: Signals obtained from the detection channel can be displayed in real-time on the screen as impedance plane graphs and time-based scan graphs. This provides a clear and detailed analysis of flaw characteristics, suitable for the stringent testing requirements of various metal materials.

Fully Digital Design: The advanced digital architecture allows for the creation and storage of multiple standard testing procedures and customized inspection routines. This empowers users to easily switch between different specifications and applications.

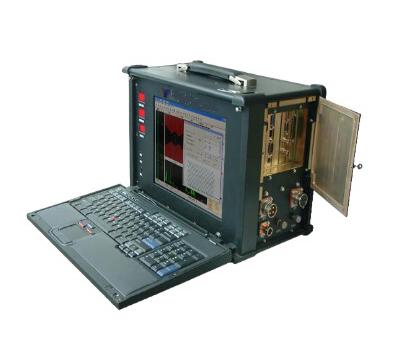

Seamless Integration: The FET99ST is furnished with a full range of input and output control connectors, enabling effortless integration with automated testing systems and other on-site equipment for a highly efficient and automated workflow.

Broad Application Spectrum: Beyond standard components, the FET99ST is also highly effective for the automatic flaw detection of other mechanical parts, including the inner walls of tubes, drill plates, bearing coils, slab holes, square billets, and round billets.

scene pictures

Advanced Data Visualization: Visualize signals in real-time with both impedance plane diagrams and time-base displays on the high-resolution screen. This dual view is suitable for the precise detection requirements of all metal materials.

Digital Efficiency: The fully digital architecture allows you to build, store, and recall multiple standard testing procedures and custom setups. This makes it exceptionally convenient for operators to switch between different component specifications quickly.

Seamless System Integration: The instrument is furnished with a full suite of input and output (I/O) control connectors, allowing it to easily connect and synchronize with external equipment to form a highly efficient, automated inspection cell."

Signal Processing & Detection

Detection Channels: 1 (Expandable upon request)

Frequency Range: 64 Hz to 10 MHz (Suitable for a wide variety of metal materials)

Gain: 0 to 90.0 dB, adjustable in 1.5 dB increments

Phase Rotation: 0° to 359°, continuously adjustable in 1° increments

Gain Ratio (Y/X): 0.1 to 10.0

Maximum Testing Speed: Up to 780 m/min

Probe Drive Level: Adjustable from 1 to 10

Digital Filtering: Independent Low-Pass (0 Hz to 2000 Hz) and High-Pass (0 Hz to 2000 Hz) filters

Balance: Fast digital and analog electronic balance

Automatic Balance Time: 1 to 1000 seconds

Alarms & Outputs

Data Management & Display

Display Modes:

Impedance Plane

Time Base Sweep

Display Options: Solid and blanking display modes

Blanking Display Coefficient: 1 to 100

Data Storage: Mass storage for testing procedures and flaw data

Signal Playback: Advanced playback function for reviewing eddy current signals, including amplitude, phase, and digital values

Automatic Recording: Automatically records flaw count and their precise locations

Automated Reporting: Generates comprehensive test reports, including total parts tested, qualified count, and unqualified count

Coordinate Systems: Selectable Rectangular (Cartesian) and Polar coordinate system backgrounds

General Specifications

Operating Language: Switchable Chinese & English interface, the interface can be customized into specific language

Clock Type: Internal and external clock options

System Clock: Automatic calendar and time display

Power Source: Rechargeable lithium battery

Battery Life: 6-8 hours of continuous operation on a single charge

Working temperature :-15~55℃

Storage temperature:-20~60℃

Relative humidity: do not exceed 85%

Working voltage :VC220V/DC24V

+86 4000-188-758

+86 4000-188-758 Chat on WhatsApp

Chat on WhatsApp