High speed eddy current flaw detector has high detecting sensitivity on the flaw of metal tubes,rods, wire such as flaw of the surface、concealed joint、air hole and surface-opening crack.

Adopting computer china menu type man-machine dialogue,big screen signal display,multi-mode alarm technique as well as special design digital electronic balance technology and intelligent dynamic filter technique,make instrument operating easier.

High speed eddy current detector can adopt crossing coils which coupling gap has very low requirements,it can also connect combined probe which is cigarette box size,the choice of probe completely can be set by detecting requirements of users. Detecting system can equipped with high accuracy delayed time marking module、testing equipment、marking machine and adjustable probe so as to realize online automatic flaw detection.

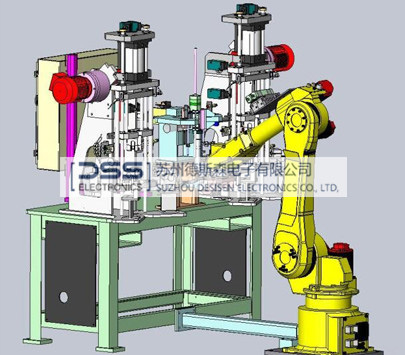

scene pictures

1、The probes don’t touch workpiece,and enhance the durability of probes

2、It can continue to detect and enhance detecting efficiency

3、It doesn’t need to change probe when detect different metal accessories,very easy to operate

4、Automatic balance、enhance instrument online detection reliability.

5、Waveform displays synchronous tracking ,make flaw signal more stable

6、No need to do magnetizing and do demagnetization,the instrument is simple and reliable

1、Channel :one set

2、Frequency :multiple

3、Detecting speed :less than 350meter per minute

4、Frequency scope:64 Hz ~ 4 MHz

5、Gains :0~90dB,stepping is 0.5dB

6、Phase position rotation:0~360° stepping is 1 °

7、Ratio of gains(Y/X):0.1~10

8、Gain/phase position measurement:manual /automatic

9、Displayed mode:spot /line /blanking

10、High pass filtering:high medium low

11、Digital filtering points

12、Working modes:inside and outside clock

13、Probe excitation signal amplitude:1-8v

14、Hardware alarm output:8pieces

15、Alarm output signal:audion OC output

Working temperature:-15~55℃

Saving temperature:-20~60℃

Relative humidity:not exceed 85%

Working voltage:AC220V±10V

+86 13616209379

+86 13616209379