- Introduction

- Function

- Parameter

- Work environment

DMD-96double frequency four channels eddy current detector possesses wide detecting frequency, the degree of stability of quartz crystal is available from 64Hz to 5MHz, therefore it is suitable for metal material which has different electric conductivity 。

The instrument adopts eddy current impedance plane and time base scanning display technology ,real time the same screen with multiple windows to show eddy signal two-dimensional diagram of detecting targets and its time base curve。All operations adopt menu type man-computer dialogue,keyboard controls,standard detecting procedure can be saved in soft disk and hard disk,convenient for user to use。Important detecting results can be fixed on the screen with text annotation,and it can be saved in soft disk and hard disk permanently ,or printed.

DMD-96 double frequency four channel eddy current detector adopts strict Db gain control,regulating variable is 0.5 dB/ grade so as to satisfy detecting standard requirements。

DMD-96 double frequency four channels eddy current detector has four physical testing channel they are cars、petrifaction、 metallurgy 、mechanism and so on 。 During detection ,it doesn’t need coupling medium and touch work piece, it is easy to realize automation 。And due to many detecting channels,it satisfies many production lines and disposable flaw detection requirement of single work piece with many detection of surface 。It is suitable for flaw detection of welded steel belt,sucker rod,valve lever ,dowel,bearing,hub,needle bearing ,hollow shaft ,bolt and so on mechanical accessories as well as metal pipes,rods,wire material 。

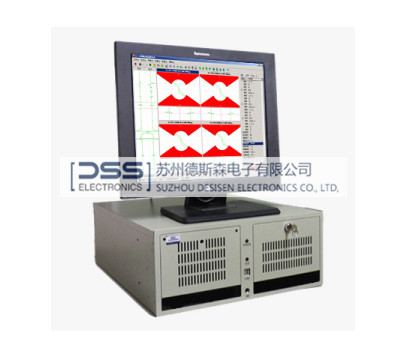

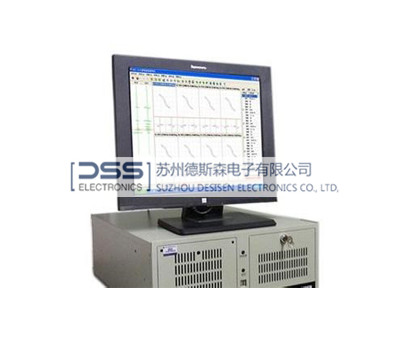

scene pictures

+86 13616209379

+86 13616209379