558H far field low frequency water wall Tube heat exchanger eddy current flaw detector isplaced on the detected material with electromagnetic base probe,there is an excitation coil as well as one or two detecting coil。The distance of excitation coil and detecting coil is two or three times of detecting material。The excitation coil sending the magnetic line can pass through material and spread to outside,and pass through tube wall which has surface flaw again and spread to inside,received by detecting coil。 Make sure the interval of Excitation coil and detecting coil

There are three areas in excitation coil and detecting coil:direct coupling area、transition area、 and far field area。The amplitude of Outside wall is bigger than inside one,when the interval is more than or equal to double detecting material, the amplitude of outside wall and inside wall will be in direct proportion to interval, and the interval is three times of material (far field area), the amplitude of outside wall and inside wall are bigger 。So the distance of excitation coil and detecting coil should be 2-3 times of inner diameter 。

Wave is spreading in material

During wave is spreading in the steel plate,amplitude is decreased,phase position will move。The thicker the material ,the fast the amplitude decreased

Distribution of Magnetic line nearby Probe

The track of magnetic line is parallel to tube wall in far field,therefore the number of magnetic line which pass the wall of material is direct proportion to the thickness of wall

scene pictures

Comparing with normal eddy current、leakage flux、ultrasonic wave nondestructive ,far field eddy current nondestructive detection has someadvantages:detected material’s surface doesn’t have to be cleaned;probe doesn’t touch the surface of material,the change of interval of probe external diameter and material inner diameter has less effect on detecting result。The sensitivity of etch pit of external surface and internal surface of detecting material is same;it has high degree of sensitivity on uniform thinning 、gradually thinning、and partial eccentric wear thinning,the detecting speed of probe is even or not which has no effect on detecting results ;the gas and liquid medium have no effect on detecting result 。Detecting equipment is small size,light weight so as to be took advantage at the scene conveniently ;the detecting data can be saved and conduct long distance detection 。

558H far field low frequency water wall tube heat exchanging tube eddy current flaw detector is a new generation eddy current nondestructive detecting equipment,it adopts the latest DSP and FPGA digital electronic technology、far field eddy current technology and microprocessor technology ,it can real time and effectively detect inwall and ektexine flaw of ferromagnetic metal tube。It doesn’t affected by probe lift-off、skin effect、Conductivity and uneven permeability 。

558H far field low frequency water wall tube heat exchanging eddy current detector is not only a whole far field eddy current detecting system,but also with properties of regular multiple frequency 、multiple channels eddy current detector ,especially having high sampling rate and super low noise and high signal -to noise ratio,make it becomes to be new type of eddy current detecting equipment with high-performance 、multiple application 、intelligence 。

558H far field low frequency water wall tube heat exchanging tube eddy current flaw detectoris used for detecting corrosion condition of water wall tube 、heat exchanging tube、downhole casing、steel、tank ,detecting equipment including signal power source 、signal measurement、and signal recording and dealing ,and producing a form which can pass through the tube ,act as piston,immediately act in the tube after supplied the power,taking advantage of built-in probe to detect gas transmission line 、download casing、buried pipeline 、heat exchanging and boiler ,taking advantage of built-in probe to detect plane and steel。Contemporary detecting equipment is taking advantage of computer to display and save data,as well as automatic signal analysis procedures。We devote into far field eddy current technology on tube detecting , especially detection on water wall tube 、heat exchanging tube、downhole casing and oil and gas pipelines。

Adaptive range and ability

corrosion erosion、abrasion 、corrosive pitting、dehiscence 、crack of Water wall tube 、heat exchanging pipe 、downhole casing 、steel tube、tank、condenser、boiler、feedwater heater、air condition

1、Having probe automatic calibration system

2、Quick analog digital electronic balance

3、Automatic (manual) eddy current signal amplitude 、phase measurement ,eddy current signal low speed (adjustable) extend playback

4、Time base scanning and impedance plane displayed on the same screen

5、Configuration Analysis function

6、Equipped with unique non amplitude phase position/amplitude alarm region

7、Hardware alarm output port

8、Saving mass detecting procedures and detecting data

9、Automatic amplitude 、phase position /flaw depth curve display

10、Background option of rectangular coordinate system and Polar coordinate system

11、Pipe cross section and number of inspected tubes are showed on the same screen

12、Hierarchically mark pipe cross section,forming overview diagram of pipe in service

13、Hierarchical statistical test results (form and histogram ) convenient to accumulate and analyze and compare。

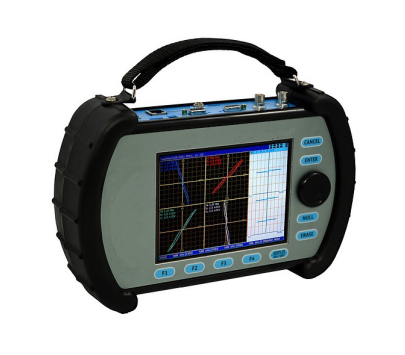

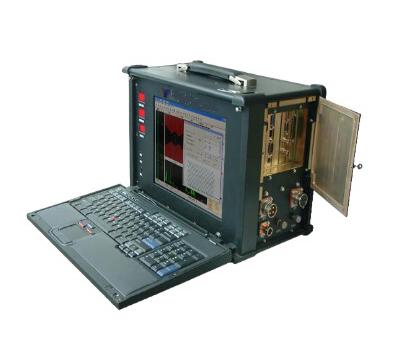

14、Table model、portable 、industrial personal computer are optional

15、Own Lithium battery (it can be used for 6-8 hours if it is charged fully )

16、Frequency scope :1 Hz ~ 5 MHz (far field frequency 1Hz~5KHz)

17、Gain :0~90dB,stepping 0.5dB

18、Phase position rotation :0~359° stepping 1 °

19、Ratio of gains (Y/X):0.1~10

20、Gain /phase position measurement :manual /automatic

21、Displaying modes:spot/line/blanking

22、High pass filtering :turn off 0~500Hz

23、Low pass filtering: turn off 10~10kHz

24、Digital filtering points :1~100

25、Probe excitation signal amplitude:1-8V, precision 1V

26、Hardware alarm output

27、Alarm output signal

28、Penetrate oxide layer thickness of steel tube surface

29、The thickness of Penetrating steel pipe: ≤ 10mm alloy steel

30、Detecting pipe diameter scope : Φ25~Φ1000mm。

31、Detecting flaw types:internal and external etch pit 、hydrogen attack 、flaw

32、Magnetizing equipment :doesn’t need

33、Demagnetization :no remanence

34、couplant :no need

35、Detecting speed : 0~8 m/min ,it can detect statically

36、Detecting technology :low frequency eddy current analysis technology

37、Man-computer dialogue:anti-dust touching screen operation

38、Displaying :with a backlit semi-anti-transparent screen ,suitable for long-term observation under darkness or sunlight

39、Scanning :three scanning modes :wipe refresh and save

40、Filtering digital and analog filtering

41、Driving :1~12V sixteen grades changeable

42、Zero setting :responsive time <0.5second

43、Preserve :preserving 、reappear more than 100items parameter and graphic data

44、Probe: shell、rubber roller 、weight ≤ 0.9 Kg。

Working temperature:-15~55℃

Saving temperature:-20~60℃

Relative humidity: not exceed 85%

Working voltage:DC24V

+86 13616209379

+86 13616209379